The development of the medical device and surgical practice.

Computational FEA studies of biomechanical behavior of a medical device have now become central to research and optimize product performance. They are tools that allow you to study the interaction with the anatomical structures in relation to biological properties trying to identify the numerical model that can lead to more faithful results possible to real conditions.

Inside the Polytechnic of Turin, at the Department of Structural Engineering, Edile and Geotechnics (DISEG), the Bioinspired Nanomechanics Lab team of Prof. Cecilia Surace composed of researchers Mariana Rodriguez, Vito Burgio and Stefano Re, in collaboration with Francesco Di Giovanni (Product Specialist at the Medistar company in Turin) and Dr. Filippo Maria Surace orthopedic surgeon, is carrying out a study of computational digital analysis to finite elements on the bone articulation sectors subjected to prosthetic surgical interventions.

The study aims to identify the correct insertion of a knee prosthesis by observing the stress conditions on the femoral and tibial bone as the resection angle of the bone tissue varies in order to better match the prosthetic components.

For the 3D acquisition stage, the Polytechnic team has equipped itself with the Einscan PRO HD Shining3D Shining3D professional scanner which, in combination with the Industrial Pack consisting of tripod and rotating table, is perfectly designed for fixed scanning with maximum accuracy which guarantees the acquisition down to the smallest detail, even for bodies under 10 cm in size. In the manual mode, however, the scanner lends itself perfectly to scanning larger components with an accuracy of up to 0.04 mm, perfect for highly detailed mechanical and electrical components.

The scanning of the femoral and tibial prosthetic components in fixed mode took no more than a few minutes, returning a precise and clean scan.

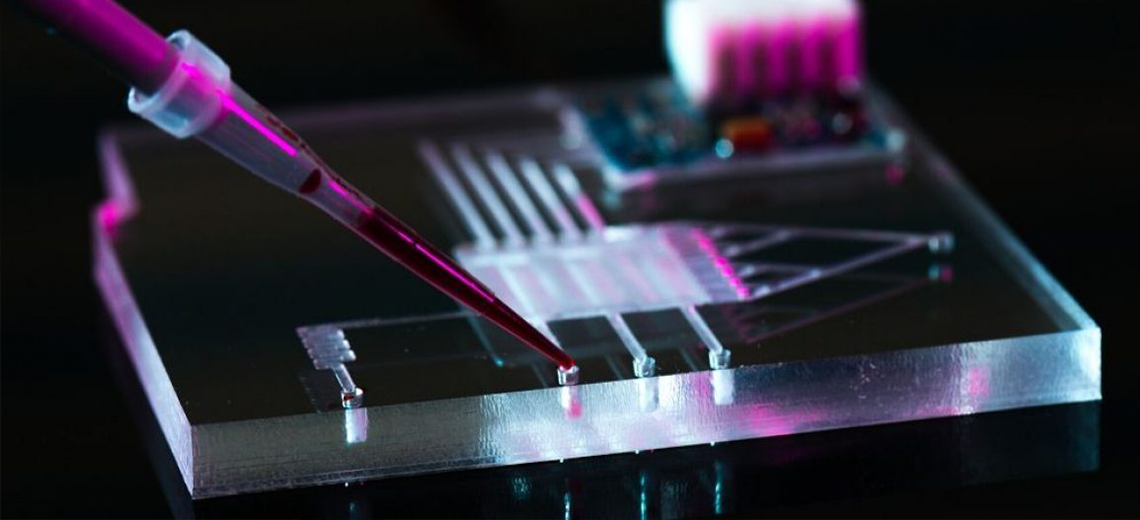

Once the scan was obtained and post-processing was carried out for the definition of the mesh suitable for numerical simulation, computational analyses were carried out with specific software, testing the bone segments of the femur and tibia reconstructed in 3D by the CT scan.

These completely digital test and validation methods favor the redesign of the medical device and pave the way for in-depth studies of structural stress, optimizing the surgical procedure to be adopted with the critical issues encountered.

Waiting for the results to which the project will lead, we can look at the potential for future applications that these fully digital test and validation methods bring to: redesign a medical device through reverse engineering, paving the way for in-depth studies of structural stress which will subsequently be optimized. the surgical procedure to be adopted with the critical issues encountered.

The use of 3D digital technologies makes possible to carry out all phases of design, validation and planning of medical devices, starting from the traditional design up to its final optimization in anticipation of the intended use. After that, all you must do is move on to 3D printing the components and tactile evaluation of the measurements, avoiding further waste of time in the operating room.