3D printing is a cutting-edge technology that has been widely used in many aspects of production and life, with numerous applications across different industries.

The medical field is gradually becoming a big application for 3D printing, with precise and personalized medical solutions brought to the table, which creates new and unique opportunities for the industry.

Research around new implant materials becomes the new requirement

In the medical industry, metal 3D printing technology has been widely used for hard tissue repair and replacement. Metal materials such as stainless steel and titanium alloys are traditional raw materials for hard tissue implants. With the promotion of 3D printing within medical applications, PEEK material has gradually emerged among many medical 3D printing raw materials, and for good reasons. PEEK has an excellent biocompatibility and is relatively easy to process and shape compared with traditional titanium used for implants. PEEK is also more X-ray transmissive and has advantages similar to bone elasticity. Because of these outstanding characteristics, PEEK has become the most important thermoplastic substitute for titanium implants, and is actually now used in production.

A Minimally Invasive Surgery for Nutcracker Syndrome Using PEEK Implant

Nutcracker syndrome, also known as left renal vein entrapment syndrome, is characterized by impeded outflow from the left renal vein into the inferior vena cava due to an abnormally narrow angle between the abdominal aorta and the superior mesenteric artery or between the abdominal aorta and the spine, resembling a nut between the jaws of a nutcracker. This phenomenon results in the formation of venous reflux, renal hilar varices, and an increase in left renal vein pressure, which mainly cause hematuria, proteinuria, and left flank/abdominal pain, as well as pelvic congestion in females and left-sided varicocele in males. Although uncommon, this diagnosis is important due to the risk of associated morbidities, including chronic kidney disease due to long-term left renal vein hypertension and left renal vein thrombosis.

Surgical treatment is the most effective treatment to relieve the compression of the left renal vein and relieve symptoms. In 2018, the Department of Urology of Tangdu Hospital in China, conducted the world’s first operation using 3D printing technology to manufacture human implants using bio-compatible PEEK material, creating another precedent for the treatment of nutcracker syndrome. PEEK printing process requires very high environmental temperature and nozzle temperature, so 3D printing equipment must be required to have a constant temperature environment and to be able to print at these high temperatures. Tangdu Hospital found in the INTAMSYS FUNMAT HT 3D printer the perfect solution to meet the needs of medical printing PEEK and to explore more opportunities with this material. The main benefits of the FUNMAT HT are its chamber temperature that can reach up to 90°C, and the extrusion nozzle that can reach 450°C, which prevents warping of PEEK printed parts.

PEEK replaces titanium alloy as the preferred implant material

In the past, the implants for this operation were mostly titanium alloys. With the deepening of 3D printing applications, PEEK has received more and more attention. As a thermoplastic engineering plastic, PEEK enjoys excellent mechanical properties and shows a good performance. Its biocompatibility, chemical resistance, easy processing and repeatable sterilization, have turned it into a substitute for titanium alloys.

According to Professor Cao Tiesheng, head of the 3D Printing Research Center of a Medical University in China, “PEEK implants have many advantages compared to the previously used titanium alloy implants. First of all, PEEK material will not affect the later medical examination of patients, such as CT, B-ultrasound, magnetic resonance medical exams, etc. At the same time, it will not cause trouble for the patient to board the plane and to go through the security check. Moreover, PEEK and its composite materials have good wear resistance, which can effectively avoid inflammation and osteolysis around the implant caused by wear particles. Therefore, the application of PEEK in orthopedic implants is considered to be one of the best candidate materials to replace traditional titanium alloy implants.”

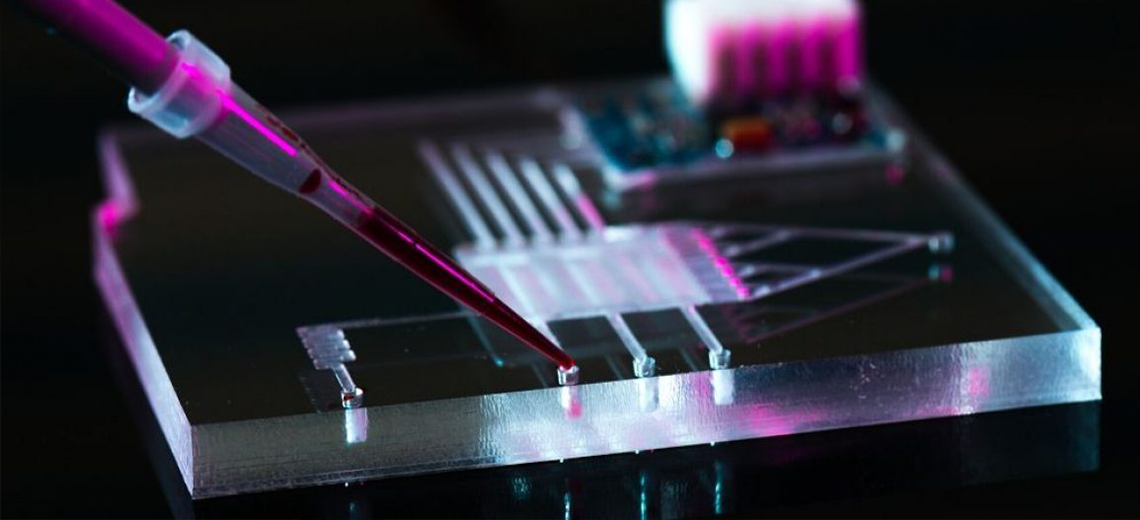

3D printing helps to achieve precise and personalized extravascular stents

With the help of 3D printing technology, the treatment method is more accurate and personalized than ever, as the artificial extravascular stents are based on the patient’s physiological anatomical structure. The doctors can now also perform preoperative verification and planning on a 1:1 model before surgery.

For the treatment of the nutcracker syndrome, Tangdu Hospital first 3D printed a prototype and verification design of the surgical stent model, based on the patient’s pathology. It then printed the PEEK implant using the INTAMSYS FUNMAT HT 3D printer, to help relieve the patient sickness.

Tangdu Hospital has an in-depth research on 3D printing solutions, especially in the applications of high-temperature materials, such as PEEK. However, the PEEK printing process requires very high environment and nozzle temperatures, so an industrial 3D printing equipment is required. Tangdu Hospital has given the INTAMSYS FUNMAT HT 3D printer a high degree of recognition for clinical application needs. In the regard, INTAMSYS signed a strategic cooperation agreement with Tangdu Hospital in May 2021. The two parties will explore the different applications of 3D printing materials within the medical field. The 3D printing solutions for medical applications, including equipment, software and materials will be continuously improved.

In order to provide Tangdu Hospital with even better research conditions, INTAMSYS has sponsored a FUNMAT PRO 410 unit, a smart multi-material 3D printer with a larger build volume, equipped with intelligent dual nozzles, which can handle a variety of complex structures and materials. The printing temperature of the nozzles can reach 500℃, and the system is equipped with a constant temperature chamber, which can better meet the needs of medical printing PEEK. This new system will enable Tangdu hospital doctors to explore even more applications and to achieve an even better precision and personalization when making medical plans for patients.

“Innovative thinking such as interdisciplinary and medical-industrial integration is a powerful means for the further development of clinical medicine, and medical 3D printing technology is such a sharp sword that can overcome practical clinical problems. I believe that in the near future, 3D printing technology will push the medical industry into an exciting new era.”

Professor Cao Tiesheng