With the aim of increasingly reducing the steps necessary for the restoration of each patient, planning plays a fundamental role because it allows you to "give life to the idea" of what each smile will look like.

Having a clear understanding of the point of arrival is certainly the first step in avoiding surprises and accepting aesthetic and functional compromises. This is the true strength of the digital workflow.

In the following case study, with the invaluable collaboration of Dott. Tommaso Costa and the CV Dental Clinic team, we tried to develop a prototype using only digital instruments and connecting:

- Intraoral scans

- Face Scans

- Individual Mandibular Movements

- 3D printing

All this was used to plan and pre-visualize every aesthetic and functional detail directly on the PC.

During the case, we focused particularly on identifying which and how much reliability there was in a completely digital work system, considering that each step could include errors or variables such as:

- Accuracy in digital record of DVO

- Couple between intraoral and facial scan

- Fidelity of mandibular movements

- Printing unknowns (print profile, orientation and nesting of the piece)

which could have given a different result between what we saw on a PC and what we would have found with the real test on a patient.

The prototyping phase therefore becomes crucial if you want to obtain a definitive prosthesis in just a few appointments. This step, in fact, allows us to collect all the guidelines, information on the patient and any changes in such a way as to be able to validate our idea of resolution of the case and proceed swiftly and safely with the realization of the definitive prosthesis, with the most appropriate materials to solve each case in the best way between aesthetics and masticatory function. In this step, therefore, it is essential for us to validate these steps and this way of operating, knowing their limits and possibilities.

One of the most innovative and functional digital data are the individual records of mandibular movements, in this case recorded by Dr. Costa with the ITAKA system. These allow us to plan the position, volume and function of each single tooth in an extremely personalized way with respect to the chewing and the function of each patient's mouth.

During the course of this case, given the experimentation of a very articulated digital flow, we preferred to also print support 3D models also experimenting with the direct printing of the Mua connections in the prototype and the direct printing of the implants on the model itself. This step allows us to validate the process and the print result against the virtual project.

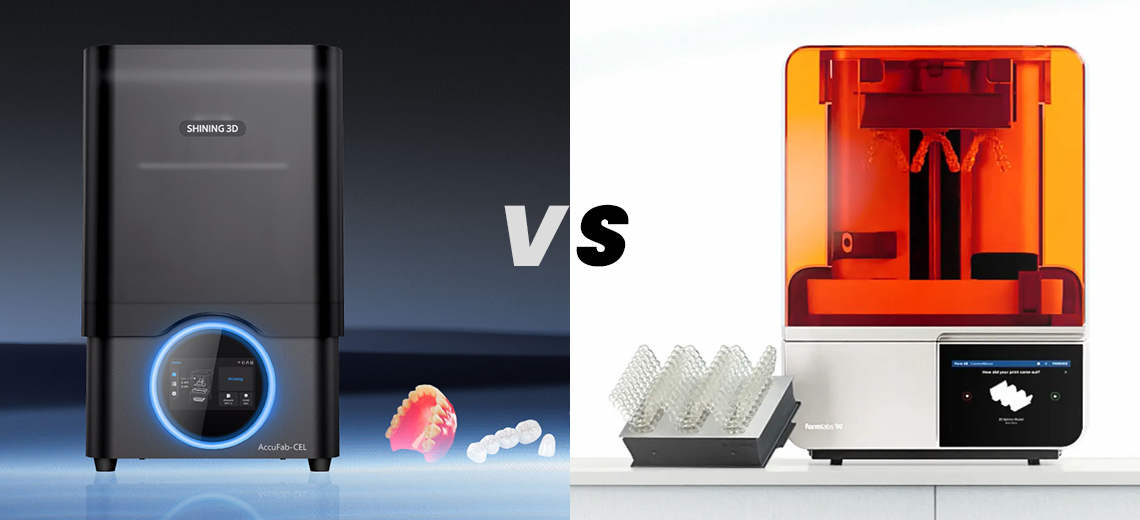

Everything was 3D printed with Shining 3D Accufab-D1s and KeyStone resins for prototypes and models. A fundamental requirement is that the entire print flow (design, printing and curing) is set up correctly: an error in this phase could jeopardize the entire acquisition and design process.

This case study investigated an extremely positive aspect related to the management of the design, prototyping and printing flow: production management and production times.

In fact, since the laboratory and clinic have the same digital system, it is easy to reduce delivery times, logistics, etc., through file sharing.

In this specific case, in Ruvo di Puglia (BA) we printed models and prototypes, and assembled everything checking that it complied with the virtual project, while in Tricesimo (UD) dr. Costa and his team could print the prototype to be tested on the patient almost simultaneously and despite the 950 km that separate us.

To do this, we not only shared the Exocad project but being lucky enough to have the same printing system set up in the same way, we were also able to share our printing project. In the studio we only had to start 3D printing.

This step was essential for the communication tool (the print file) to be identical: oriented in the same way and printed in the same position, because sometimes the nesting of the object to be printed can have a significant difference both positively but even negatively.

Through the total digitization of the patient it is much easier to analyse, compare, measure and verify each technical and clinical step through a single term of comparison: the personal file relating to each patient containing everything it concerns him (intraoral scans, facial scans, static occlusion, dynamic movements).

With this approach, and having a single point of reference containing not only the information relating to the patient but also the possible solutions to better resolve his clinical case, it is possible to plan, evaluate and execute any treatment, virtually managing to pre-visualize with a good percentage of success what will be the final result.

The higher that percentage is, the greater the possibility of "promising" something to the patient and being able to obtain the same thing without compromises or variations.

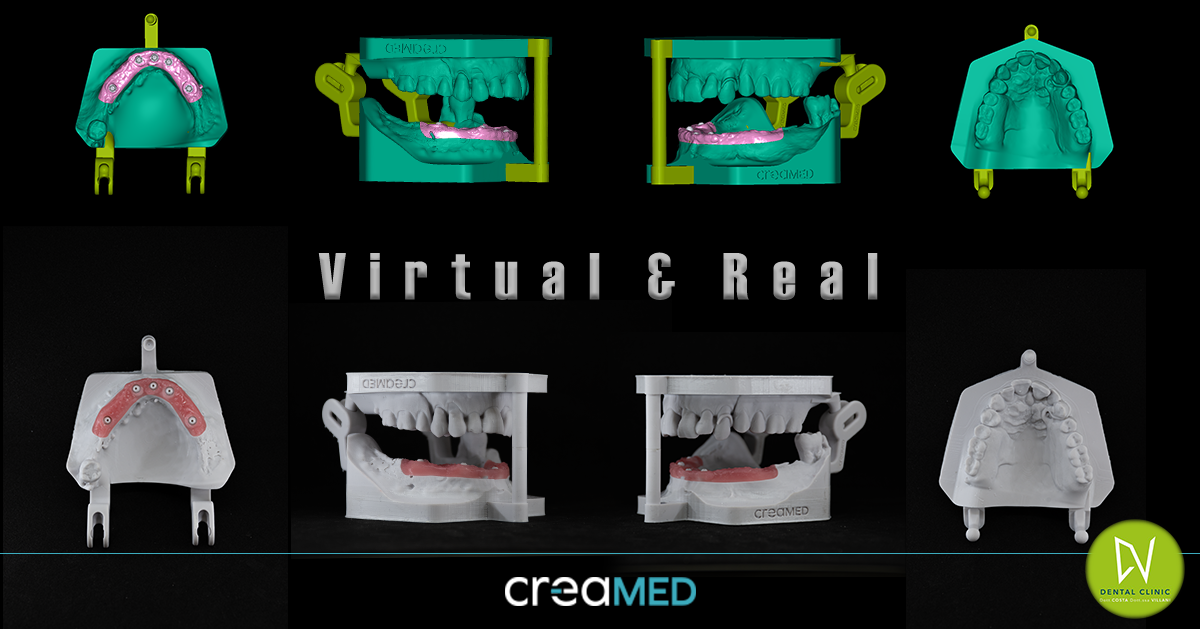

In the photos below we tried to make a comparison between what was digitally/virtually recorded and programmed and what we actually managed to achieve: real and virtual have never been so similar .

From virtual to real also in dynamics

After verifying the complete effectiveness of the prototyping process (acquisition, design, printing) which found the exact match in reality, we ascertained how not only the contacts in static occlusion, but also the dynamics were perfectly equal to those made in the planning stage.

In conclusion, we can say that the prototyping phase plays a fundamental role in the validation of the entire digital process and in the approach to solving each clinical case. In this step, in fact, an important game is played between what can be promised to the patient and what one is really able to obtain and the point of arrival is also clearly and clearly established. Thinking from this point of view, even the surgical planning, the choice of material and the type of prosthesis to be made are facilitated by the guidelines (spaces, shapes, volumes) that the validated prototype was able to provide us.

A huge thank you to Dr. Tommaso Costa and all the CV Dental Clinic staff for sharing this experience with us.