In the world of dental 3D printing, the choice between an open system and a closed system can significantly impact productivity, costs, and operational flexibility.

In this article, we will exam the crucial differences between an open system, using the Shining 3D Accufab-CEL dental printer as a reference, and a closed system like the Formlabs Form 4B printer, evaluating several fundamental parameters in detail.

1. What’s an Open System?

An open system, such as the Accufab-CEL printer, allows the use of third-party resins, enabling the customization of print parameters based on the user's technical capabilities. This provides greater flexibility in material selection and can lead to lower operating costs. The results are always guaranteed by the print profiles that the company, in this case SHINING, makes available to the user for a wide range of materials.

2. What’s a Closed System?

A closed system, like the Formlabs Form 4B printer, is designed to work exclusively with proprietary materials supplied by the printer manufacturer. This ensures optimal compatibility and consistent print quality.

Advantages of the Open System:

- Material Flexibility: Ability to use a wide range of resins from different manufacturers.

- Less Costs: Variable costs based on the materials used and the print parameters settings.

- Updates and Innovations: Easly integration of new materials as they become available on the market.

- Variable Quality: Possibility of achieving extremely precise prints by using quality resins and fine-tuning print parameters.

Disadvantages of the Open System:

- Learning Curve: The user can make the difference by expanding their knowledge and using quality materials, but they must learn how to use the printer and software effectively.

- Technical Support: Greater responsibility in terms of configuration and troubleshooting, unless supported by a provider that assists their customers.

Advantages of the Closed System:

- Consistent Quality: Optimization between hardware and materials, always ensuring print results.

- Support and Maintenance: Limited technical support needed due to the use of certified materials and profiles by the manufacturer.

- Ease of Use: Simplified processes and preset configurations that minimize the need for user intervention.

Disadvantages of the Closed System:

- Higher Costs: Proprietary materials tend to be more expensive.

- Less Flexibility: Limitations in material choice and less adaptability to new resins.

- Unimprovable Quality: Inability to use other materials and fine-tune print precision, preventing the achievement of top-tier results.

3. Printable Materials and Resin Costs

One of the fundamental aspects related to printing possibilities is the range of available materials and the applications that the machine can develop. In this regard, both the Form 4B and the Accufab-CEL offer various materials that enable the printing of models, surgical guides, temporaries, permanents, bite splints, impression trays, aesthetic try-ins, bone prototypes, artificial gums, and castable resins.

Dental resins for an open system

Dental resins for an open system

Formlabs dental resins

Formlabs dental resins

Below is a table showing the cost/litre for all applications:

| Applications | Resine Accufab-CEL (cost per L/Kg) |

Resine Form 4B (cost per L/Kg) |

| Models | HPdent Inovaprint model | Xtra 75,00 € KeyModel Ultra 83,00 € Shining3D DM12 120,00 € |

Fast Model Resin 120,78 € Precision Model Resin 157,38 € |

| Temporary | Bego VarseoSmile Temp 498,00 € |

Temporary CB 913.78 € |

| Permanent | BEGO TriniQ 999,00 € Saremco CrownTech 1240,00 € |

Permanent CB 936,80 € |

| Dental trays | Shining3D TR01 135,00 € |

Custom Tray 303,78 € |

| Castable | BEGO VarseoWax CAD/Cast 314,00 € Shining3D DC12 160,00 € |

Castable Wax Resin 364,78 € |

| Surgical Guides | Shining3D SG01 150,00 € KeyGuide 249,60 € |

Surgical Guide Resin 303,78 € |

| Bite | KeySplint Soft / Hard 442,00 € |

Dental LT Comfort 523,38 € Dental LT Clear 425,78 € |

4. Economic Comparison of Routine Work

Given the material costs, we can now simulate a workflow for printing a model and evaluate the overall job cost.

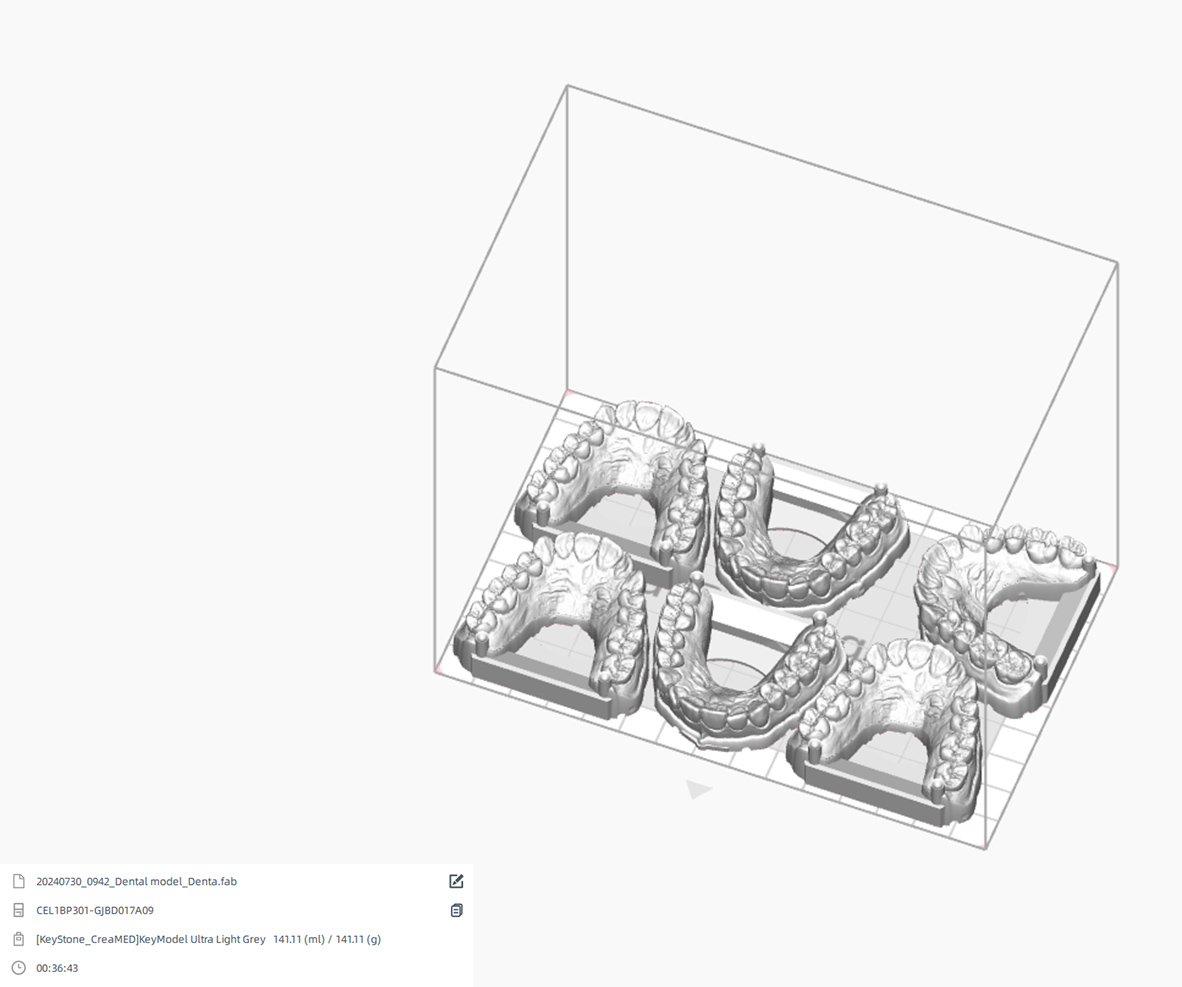

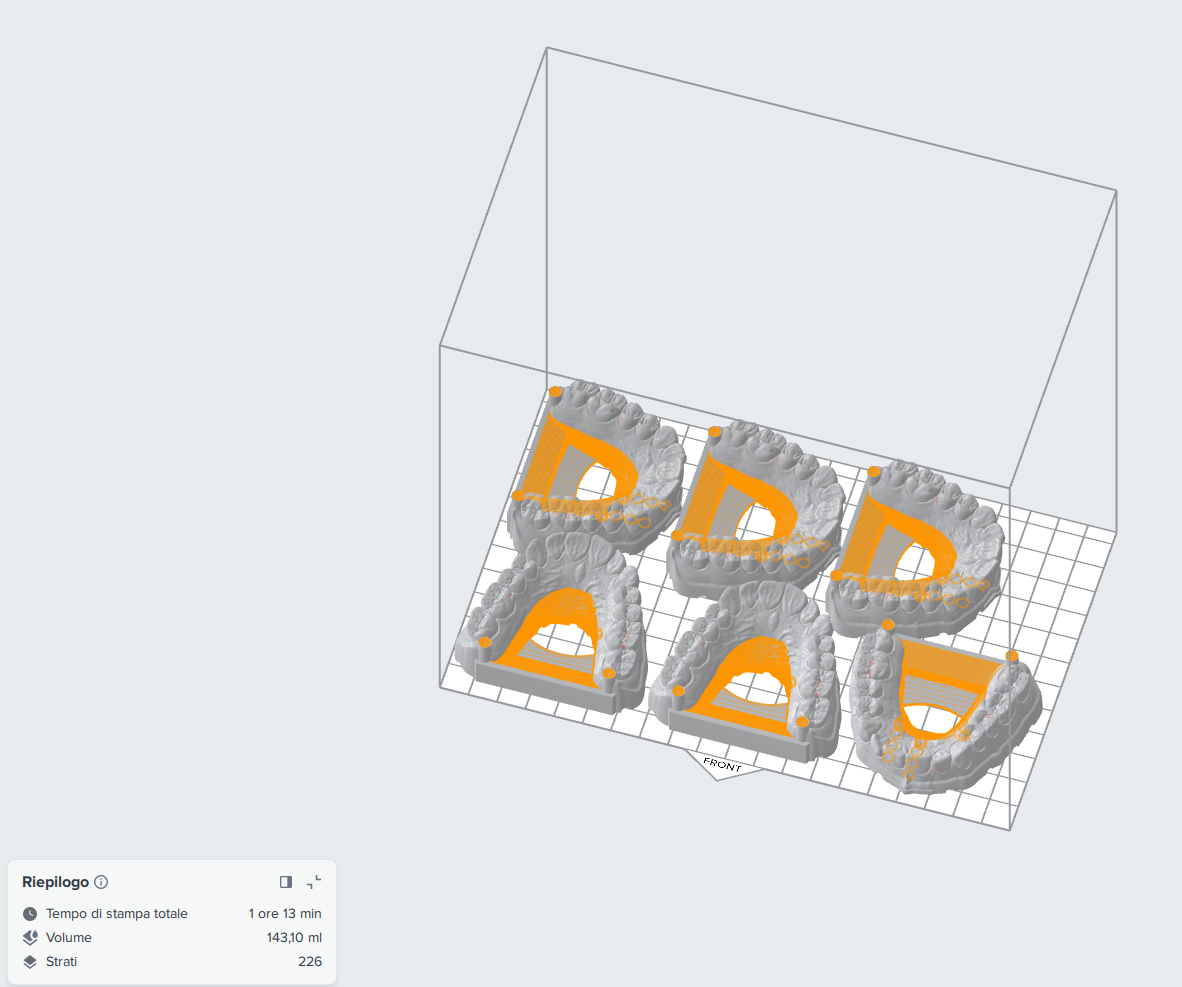

Beyond the cost of the machine itself, in this example, we attempted to calculate the management costs and consumption over a 1-year work period. We considered a sample model and compared the print reports.

On both the Accufab-CEL and the Form 4B, we can place the same number of models, but we can immediately notice that the print time for the Accufab-CEL is 36 minutes, compared to 1 hour and 13 minutes for the Form 4B, which translates into significant advantages.

| Accufab-CEL | Form 4B | |

| Number of models on the platform | 6 | 6 |

| Layer height | 100 Micron | 100 Micron |

| Amount of resin used | 141ml | 143ml |

| Estimated Time | 36min | 1h 13min |

| Resin cost per kg | 83,00 € | 120,78 € |

Slicing with AccuWare

Slicing with PreForm

5. Conclusions

Considering a cost difference of €37/kg in favor of KeyModel Ultra Light Grey resin compared to Fast Model Formlabs, let's make a print forecast for 12 months, with an average consumption of about 2 kg of resin per month, equating to approximately 80 models.

| 12 Month Forecast | Accufab-CEL | Form 4B | Savings |

| Resin: 24 Bottles (2kg/month) | 1.992,00 € | 2.898,72 € | 906,72 € |

| Number of prints | 160 | 160 | - |

| Working hours | 96 | 195 | 99 working hours |

We note a saving of €906.72 (approximately 10 bottles of Keystone resin) and about 99 hours less work, which also justifies reduced wear on the machine and lower electricity consumption.

| AccuFab-CEL | Form 4B | |

| Technology | LCD 6K | LCD 4K |

| Price | €5.900 | €7.440 |

| Resolution | 35 microns XY | 50 microns XY |

| Print Volume | 192 x 120 x 180 mm 70 x 70 x 180 mm |

200 x 125 x 200 mm |

| Max Speed | 100 mm/h | 100 mm/h |

| Resins | Open System | Closed System |

| Interconnessione Industria 4.0 |

Present | Present |

Comparison table of technical parameters of the two printers