With the modern Additive Manufacturing systems, it is possible to produce high-performance customized orthotics at a lower cost.

The integration between stabilometric and baropodometric survey systems, that let you make an anatomical and functional evaluation of the foot, and CAD modelling software, allows you to optimize and vary the inner filling for optimal comfort and greater strength and security.

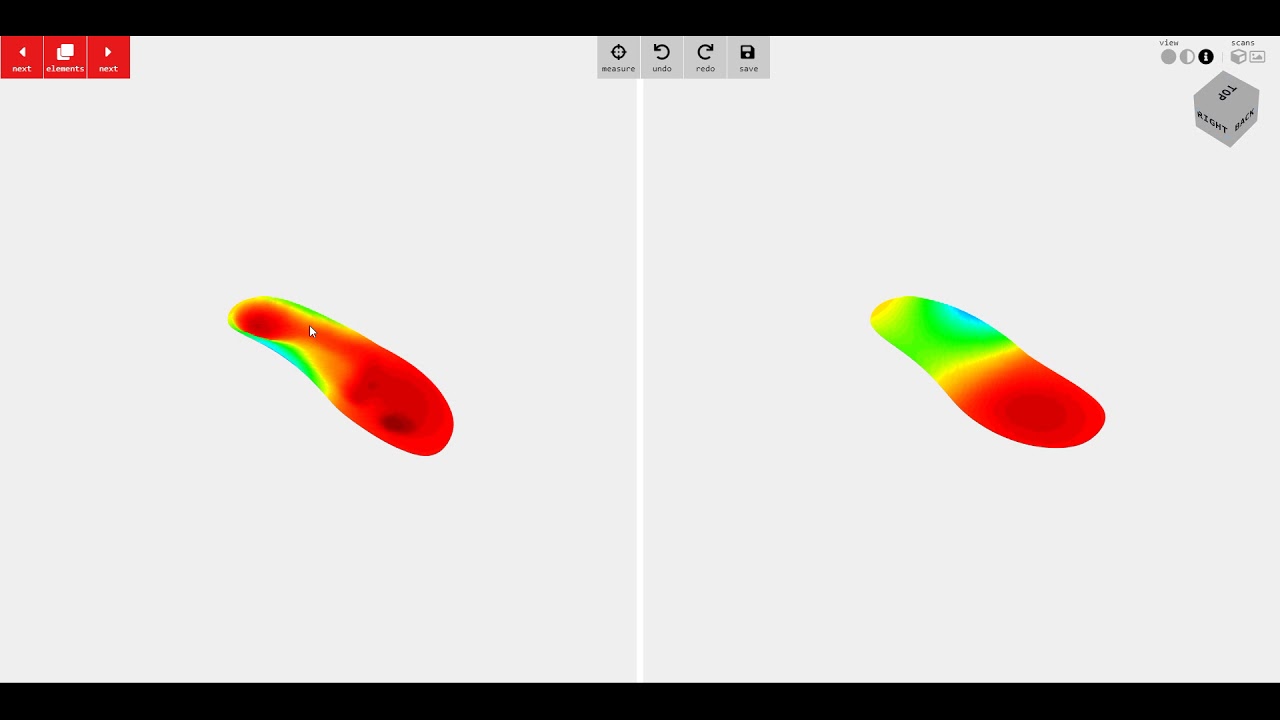

design and orthotic refinement through LutraCAD and Meshmixer software

By using a 3D printer, it is possible to produce orthotic devices with different materials and parameters and create highly functional and customized products.

The FFF technology works by overlapping layers, melting together various layers and creating an internal filling able to use patterns and always different and optimizable configurations.

Thanks to their materials database and to a series of pre-set parameters, slicing software allow to get a G-CODE and a process start in a very short time.

orthotic parameterization through Meshmixer software

3D printed orthotic can meet the needs of patients affected by different pathologies or athletes who need a thin and light orthotic, suitable even for tight footwear, that is both stiff but comfortable.

Due to a low start-up cost and to the innovative technopolymers application, you can manufacture orthotics and products without any geometrical or dimensional constraint.

The range of materials can vary from ABS to elastomers of different Shore hardness, up to glass or carbon fiber filaments.

Compared to traditional CNC machines, 3D printers offer different operational benefits:

- Printer cost lower than CNC pantograph

- Availability of different materials and filaments, which do not require a high warehouse space

- Lower price per single part

- Possibility to vary the density at each point and/or height of the orthotic

- Possibility to create orthotics with flexible or carbon fiber material for sports applications

- Quicker ROI

At the moment the Additive Manufacturing processing prove to be less rapid in comparison to cutting processing.

However, it is possible to optimize printing times using different diameter extruders and materials suitable for high speed printing.

preparazione alla stampa dei plantari con il software Ultimaker Cura

| MATERIAL | DURATION | COST |

| TPU 80A LF | 6h 44m | € 6.40 |

| Nylon CF | 10h 2m | € 7.89 |

Timing and costs for orthotics realization by means of 3D printing, using different materials.